Unleashing Creativity with 3D Metal Printing

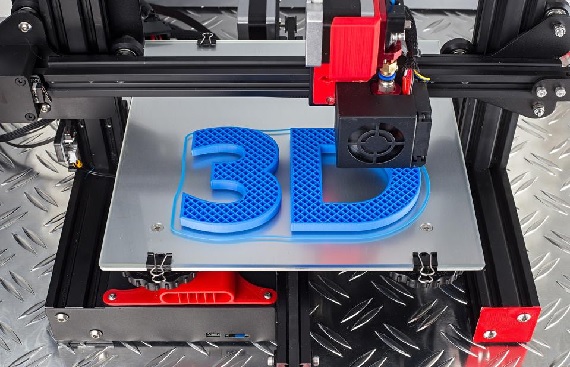

In recent years, 3D printing has become a powerful tool for creative expression and design innovation. With the development of metal 3D printing, designers and engineers now have access to a new realm of possibilities for bringing their ideas to life. In this, we will explore how 3D metal printing has opened up new avenues for creativity and how it is revolutionizing the way we approach design and manufacturing.

The Rise of Metal 3D Printing

3D printing, also known as additive manufacturing, has been around for several decades. However, it was only in the last decade that the technology has made significant strides, becoming more accessible and affordable. One of the most exciting developments in 3D printing technology has been the rise of metal 3D printing.

Metal 3D printing is the process of using a laser or electron beam to melt metal powder and fuse it together layer by layer to create a solid, three-dimensional object. This technology allows designers and engineers to create complex geometries that were previously impossible with traditional manufacturing techniques. This makes metal 3D printing an ideal solution for producing parts with intricate designs or for creating customized parts with a high degree of precision.

Pushing the Limits of Design

Metal 3D printing has opened up new avenues for designers to push the limits of what is possible with their designs. With traditional manufacturing methods, it can be difficult or impossible to create complex geometries. However, with metal 3D printing, designers can create parts with complex internal structures or intricate shapes that were previously impossible to produce.

One example of how metal 3D printing is pushing the limits of design is in the aerospace industry. Aerospace parts often require complex geometries to achieve the desired performance characteristics. With metal 3D printing, designers can create parts that are lighter, stronger, and more durable than traditional manufacturing methods.

Customization and Personalization

Another area where metal 3D printing is having a significant impact is in customization and personalization. With traditional manufacturing methods, it can be challenging and expensive to produce customized parts or products. However, with metal 3D printing, designers can create customized parts with a high degree of precision and accuracy.

One example of how metal 3D printing is being used for customization is in the medical industry. With metal 3D printing, it is possible to create custom implants that are tailored to the patient's unique anatomy. This can improve the outcome of surgical procedures and reduce the risk of complications.

Sustainable Manufacturing

Sustainability is becoming an increasingly important consideration in manufacturing. With metal 3D printing, it is possible to reduce waste and increase sustainability in the manufacturing process. Traditional manufacturing methods often produce a significant amount of waste material. However, with metal 3D printing, designers can create parts with a high level of accuracy, reducing the amount of waste material produced.

The Future of Metal 3D Printing

Metal 3D printing is still in its early stages, and there is a lot of room for growth and innovation. As the technology continues to evolve, we can expect to see even more exciting developments in the field of 3D printing. One area that is likely to see significant growth is in the use of metal 3D printing for mass production.

Mass production is an area where metal 3D printing has the potential to disrupt traditional manufacturing methods. With metal 3D printing, it is possible to produce parts with a high degree of precision and accuracy at a much faster rate than traditional manufacturing methods. This could lead to

significant cost savings and increased efficiency in the manufacturing process.

Materials and Applications

As metal 3D printing continues to develop, new materials and applications are emerging. One area of interest is the development of new metal alloys for 3D printing. These new alloys could have unique properties that make them ideal for specific applications.

One potential application for metal 3D printing is in the production of complex molds for injection molding. With metal 3D printing, it is possible to create molds with complex geometries that were previously impossible to produce. This could lead to more efficient and cost-effective injection molding processes.

Another area of interest is the use of metal 3D printing for the production of customized jewellery and accessories. With metal 3D printing, it is possible to create intricate designs that would be difficult or impossible to produce with traditional manufacturing methods. This could lead to new opportunities for designers and artists in the fashion industry.

Finally, we can conclude that 3D metal printing has become a game-changer in the world of manufacturing and design innovation. With its ability to create complex geometries, customize parts with high precision, and reduce waste in the manufacturing process, metal 3D printing has opened up new possibilities for designers and engineers. As the technology continues to evolve, we can expect to see even more exciting developments and applications of metal 3D printing in various industries. From aerospace to medical to fashion, metal 3D printing is revolutionizing the way we approach design and manufacturing, and the possibilities for creativity and innovation are endless.