Dr. Ankush Oberoi, President & CEO

Lavorro, a leading expert in smart fabrication manufacturing, fabrication tools, and process control, has emerged as a frontrunner in the application of cutting-edge software solutions to help businesses overcome the inefficiencies of the semiconductor industry.

“Our mission is to make the semiconductor manufacturing process smarter and address industry challenges to improve overall equipment and production efficiency,” says Dr. Ankush Oberoi, CEO of Lavorro.

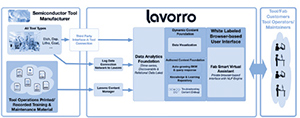

The advancement of fab technologies and the complexity of the processes and their supporting tool sets have made it rare to find a company that possesses the digital finesse Lavorro exhibits in its approach toward optimizing semiconductor manufacturing processes. The company has recognized the need to overcome constraints posed by a limited pool of subject matter experts (SME) as well as a shortage of on-premise, knowledge-based solutions. In light of this, it harnessed the potential of artificial intelligence (AI), machine learning (ML), and advanced natural language processing (NLP) technology to develop a Virtual Assistant and a Data Broker software platform. These game-changing software solutions provide real-time expertise and instant access to vital content and tool data, equipping manufacturing teams with the resources needed to optimize operations.

Lavorro's virtual assistant captures expert knowledge, complete documentation of manuals and best-known methods, as well as custom views of critical tool parameters, enabling access to invaluable expertise directly at the tool side. As an early adopter of NLP technologies, the company also offers interactive queries of tool documentation and system performance through the Lucy BOT assistant, which operates locally and addresses IP concerns related to remote cloud systems. Partnering with leading integrated device manufacturers (IDM) and foundries worldwide, Lavorro recognizes that automation significantly improves fab efficiency and wafer yield. However, most fab tools are not linked to a data bus for exchanging tool data due to technology challenges. To overcome this, in addition to the Data Broker software platform, it developed a flexible bus architecture called L-Bus to facilitate data transfer between tools in the fab.

Lavorro has streamlined this journey by developing a platform called Silicon Bridge, which enables fabs to monitor the performance of all Data Broker-linked and associated tools with wafer yield information. This technological advancement empowers semiconductor manufacturers to use historical tool data, analyze it, and facilitate fault isolation and containment with ease.

Lavorro's comprehensive suite of on-premise solutions represents a paradigm shift in the industry, offering optimization of tool performance, as well as enhancing fab uptime and availability by fully leveraging its expertise and cross-tool data sets. Suppliers can also substantially reduce expenses by controlling labor costs and travel budgets, driving operational efficiency and improving the bottom line.

Exploring the Multifaceted Benefits of Lavorro's Remote Solutions

Data Pipelining: Content Standardization and Normalization

The innovative data pipelining approach of Lavorro’s solutions unlocks the full potential of buried data streams in semiconductor tool control software. Its state-of-the-art, Virtual Assistant platform offers a robust set of tools, including content standardization and normalization, as well as processing and parsing capabilities. It also provides a flexible data framework that joins custom tool data formats into a normalized, easily queried data lake with data visualizers and external API connections.

To ensure maximum efficiency and query performance, advanced schema development techniques with efficient compression for long-term data storage have been incorporated. In addition, stored fab tool data is directly connected to the natural language conventions found in all procedural, troubleshooting and training content, enabling the rapid synthesis of new operational processes.

Future Proofing with ML-Enabled Foundations

Lavorro specializes in leveraging the latest advancements in AI to create innovative analytics tools for semiconductor process engineering.

Using cutting-edge statistical ML, generative AI techniques, and advanced agent-based AI, the company is committed to providing its clients with the most advanced AI technologies.

Its ML-enabled foundations also offer a distinct advantage in empowering tool owners, operators, and process engineers with real-time access to current and historical data. The resource-rich platform enables modern ML techniques to be applied to the tool’s time-series metrics or wafer-level insights. This innovative approach enables Lavorro’s clients to predict, detect, or classify unexpected tool downtimes or maintenance periods, empowering operators to make quick and informed decisions.

By investing in cutting-edge AI technology, Lavorro ensures its clients are well-positioned for long-term success and future-proofs their businesses in the face of rapidly evolving technological advancements.

Content Discovery—Knowledge Management and Common Language

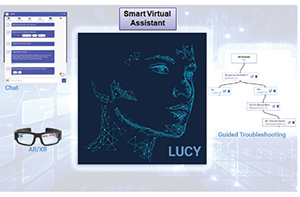

Lavorro’s groundbreaking NLP platform, Lucy, revolutionizes the way semiconductor manufacturing environments communicate. Despite SEMI's efforts to establish common language in the manufacturing environment, inconsistencies abound when it comes to authoring tool manuals, best-known-method write-ups, operator notes, and post-mortems. However, Lavorro's NLP platform is the first-of-its kind to be semiconductor language-aware while preserving the proprietary nature of the content authored within the fab environment.

Lucy's standardization capabilities, combined with the ability to customize dictionaries for use in large fab environments, make it easy for newer and less experienced fab technicians to locate and understand the required documents without encoding or reinterpreting the questions used by other technicians and authors. Its generative AI allows them to customize dictionaries and create tool-related conversational AI tailored for each process domain. The NLP platform is trained specifically to produce query results that protect confidential customer data, ensuring the highest level of data security.

Using the Lucy platform is a breeze. Operators can search, ask questions, and investigate data in real-time while senior technicians can draft rapid responses on the fly. These tools enable consistent, quick knowledge capture and dissemination across tools, work shifts, and fab sites. They also act as a force multiplier for hard-to-find senior technology team members whose tribal knowledge is highly sought after, but frequently lost.

Lavorro's NLP platform is a game-changer for the semiconductor manufacturing industry, paving the way for improved communication and streamlined knowledge sharing across all levels of expertise. Its state-of-the-art technology offers enterprise-grade security and customization, making it an essential tool for any modern manufacturing facility.

"Our NLP solution stands out from the rest because it is uniquely domain-oriented. Its deep understanding of the idiosyncrasies and language of this industry allows it to accurately interpret even the most nuanced terms, making it an invaluable asset in addressing the complex needs of this domain," says Dr. Oberoi.

IP Protection—Cloud First Design, On-Premise Deployment

Lavorro has meticulously incorporated years of internet security and deployment best practices to ensure a robust and agile foundation for its products. It employs cutting-edge tools, like a containerized environment with software defined networks, to provide unparalleled flexibility in deployment scenarios. These tools empower Lavorro's technology to be effortlessly installed on bare-metal hardware, such as semiconductor manufacturing equipment, and seamlessly integrated with rapidly evolving private clouds in fab data centers.

On-premise deployments offer another strategic advantage by leveraging existing fab-security provisions. Data protection, triple-A foundation, and in-flight/at-rest encryption can also be seamlessly deployed and integrated with authorized/role-based systems on MES and other fab software solutions. This security framework makes Lavorro's solution a reliable choice for organizations seeking to safeguard their valuable data assets.

Augmented Reality

Lavorro's solutions for optimizing fab environments are indispensable, and its augmented reality (AR) headgear with a heads-up display (HUD) is particularly noteworthy. Its team of experts are redefining the industry by making operators’ jobs not only more efficient, but more enjoyable.

While not all fabs offer remote access, those that do can experience substantial benefits by using the remote escalation capability. Wearing the HUD, one may easily contact a support specialist and view exactly what the technician sees, potentially saving thousands of dollars in field service engineer (FSE) travel and reducing time spent on resolving issues.

Its ML-enabled foundations also offer a distinct advantage in empowering tool owners, operators, and process engineers with real-time access to current and historical data. The resource-rich platform enables modern ML techniques to be applied to the tool’s time-series metrics or wafer-level insights. This innovative approach enables Lavorro’s clients to predict, detect, or classify unexpected tool downtimes or maintenance periods, empowering operators to make quick and informed decisions.

By investing in cutting-edge AI technology, Lavorro ensures its clients are well-positioned for long-term success and future-proofs their businesses in the face of rapidly evolving technological advancements.

Content Discovery—Knowledge Management and Common Language

Lavorro’s groundbreaking NLP platform, Lucy, revolutionizes the way semiconductor manufacturing environments communicate. Despite SEMI's efforts to establish common language in the manufacturing environment, inconsistencies abound when it comes to authoring tool manuals, best-known-method write-ups, operator notes, and post-mortems. However, Lavorro's NLP platform is the first-of-its kind to be semiconductor language-aware while preserving the proprietary nature of the content authored within the fab environment.

Lucy's standardization capabilities, combined with the ability to customize dictionaries for use in large fab environments, make it easy for newer and less experienced fab technicians to locate and understand the required documents without encoding or reinterpreting the questions used by other technicians and authors. Its generative AI allows them to customize dictionaries and create tool-related conversational AI tailored for each process domain. The NLP platform is trained specifically to produce query results that protect confidential customer data, ensuring the highest level of data security.

Using the Lucy platform is a breeze. Operators can search, ask questions, and investigate data in real-time while senior technicians can draft rapid responses on the fly. These tools enable consistent, quick knowledge capture and dissemination across tools, work shifts, and fab sites. They also act as a force multiplier for hard-to-find senior technology team members whose tribal knowledge is highly sought after, but frequently lost.

Lavorro's NLP platform is a game-changer for the semiconductor manufacturing industry, paving the way for improved communication and streamlined knowledge sharing across all levels of expertise. Its state-of-the-art technology offers enterprise-grade security and customization, making it an essential tool for any modern manufacturing facility.

"Our NLP solution stands out from the rest because it is uniquely domain-oriented. Its deep understanding of the idiosyncrasies and language of this industry allows it to accurately interpret even the most nuanced terms, making it an invaluable asset in addressing the complex needs of this domain," says Dr. Oberoi.

IP Protection—Cloud First Design, On-Premise Deployment

Lavorro has meticulously incorporated years of internet security and deployment best practices to ensure a robust and agile foundation for its products. It employs cutting-edge tools, like a containerized environment with software defined networks, to provide unparalleled flexibility in deployment scenarios. These tools empower Lavorro's technology to be effortlessly installed on bare-metal hardware, such as semiconductor manufacturing equipment, and seamlessly integrated with rapidly evolving private clouds in fab data centers.

On-premise deployments offer another strategic advantage by leveraging existing fab-security provisions. Data protection, triple-A foundation, and in-flight/at-rest encryption can also be seamlessly deployed and integrated with authorized/role-based systems on MES and other fab software solutions. This security framework makes Lavorro's solution a reliable choice for organizations seeking to safeguard their valuable data assets.

Augmented Reality

Lavorro's solutions for optimizing fab environments are indispensable, and its augmented reality (AR) headgear with a heads-up display (HUD) is particularly noteworthy. Its team of experts are redefining the industry by making operators’ jobs not only more efficient, but more enjoyable.

While not all fabs offer remote access, those that do can experience substantial benefits by using the remote escalation capability. Wearing the HUD, one may easily contact a support specialist and view exactly what the technician sees, potentially saving thousands of dollars in field service engineer (FSE) travel and reducing time spent on resolving issues.

In modern fabs, communication is often difficult due to noise levels. However, Lavorro's person-to-person communications capability allows two technicians to communicate using AR headsets with built-in microphones and cameras that are seamlessly integrated with the Lucy BOT. This allows for a smooth and clear transfer of information in the environment.

The HUD also offers the ability to transfer dashboards and issue voice commands to gather technical data monitored by the BOT. In addition, if cameras are permitted in the fab, the HUD captures videos and still images that can be easily incorporated into Lucy's training modules and troubleshooting guides.

Lavorro is continuously pushing boundaries and exploring exciting opportunities using cutting-edge AR headsets and enabling the fully animated Lucy BOT to interact with a tool in 3D when models are available. With tools like the heads-up assistant, it is positioning itself as a critical player in silicon smart manufacturing solutions.

“Our NLP solution stands out from the rest because it is uniquely domain-oriented. Its deep understanding of the idiosyncrasies and language of this industry allows it to accurately interpret even the most nuanced terms, making it an invaluable asset in addressing the complex needs of this domain”

Impactful Implementations

Lavorro is recognized for its successful collaborations with esteemed global clients, delivering solutions that work seamlessly in multiple use cases. Among those that stand out as truly exemplary involve Lavorro's real-time collection, normalization, and historical record keeping of tool sensor data, allowing tool SMEs to quickly investigate tool performance and misbehavior. By reducing the extra effort to merge, clean up, and analyze historically difficult log files, it has effectively reduced the time required to address these issues from days or weeks to a few moments.

Lavorro has worked closely with multiple customers to develop predictive failure models based on detailed tool data, resulting in reduced downtime, increased lifespan, and decreased operational costs. This has been a game-changer for many clients, providing them with an unprecedented level of insight into their tools' behavior and allowing them to take proactive measures to address potential issues.

Other notable benefits involving Lavorro's platform is the computation of measurements, particularly in the area of time-series analysis. This gives customers unique insights into variability they have not seen before, contributing significantly to process uniformity and allowing them to adjust their engineering solutions to correct any deviations.

Staying Ahead of the Game

At the helm of Lavorro stands Dr. Oberoi, an industry luminary renowned for his pioneering work in advanced technologies like Fab wide Predictive Yield Management, Cad Navigation and on-tool design based applications that revolutionized the semiconductor manufacturing landscape. Under his tutelage, the company has brought to bear a high level of yield improvement knowledge, now extending to the tool level while simultaneously providing cutting-edge framework for seamless tool-to-tool collaboration.

Out of all the ways in which Lavorro stands out from its competitors in the semiconductor industry, notable is its adoption of a collaborative engagement model. This approach entails working closely with semiconductor fabs and tool suppliers to identify complementary software solutions for tool performance, maximizing the benefits of its platform for all stakeholders.

Driven by its unwavering pledge to deliver tangible, measurable results and achieve operational excellence for its clients, Lavorro functions as an invaluable partner for any organization looking to optimize operations, streamline processes, and boost their bottom line. With its finger on the pulse of latest industry trends and developments, the firm is poised to continue blazing a trail toward a brighter, more efficient semiconductor manufacturing future.

The HUD also offers the ability to transfer dashboards and issue voice commands to gather technical data monitored by the BOT. In addition, if cameras are permitted in the fab, the HUD captures videos and still images that can be easily incorporated into Lucy's training modules and troubleshooting guides.

The HUD can also be integrated into troubleshooting guides, allowing a seamless transition between steps. A user can follow the instructions displayed on the glasses, which will direct them to a specific location on the tool using QR codes or descriptions. It can also control the Lucy BOT, ensuring a streamlined problem-solving process.Our mission is to make the semiconductor manufacturing process smarter and address industry challenges to improve overall equipment and production efficiency

Lavorro is continuously pushing boundaries and exploring exciting opportunities using cutting-edge AR headsets and enabling the fully animated Lucy BOT to interact with a tool in 3D when models are available. With tools like the heads-up assistant, it is positioning itself as a critical player in silicon smart manufacturing solutions.

“Our NLP solution stands out from the rest because it is uniquely domain-oriented. Its deep understanding of the idiosyncrasies and language of this industry allows it to accurately interpret even the most nuanced terms, making it an invaluable asset in addressing the complex needs of this domain”

Impactful Implementations

Lavorro is recognized for its successful collaborations with esteemed global clients, delivering solutions that work seamlessly in multiple use cases. Among those that stand out as truly exemplary involve Lavorro's real-time collection, normalization, and historical record keeping of tool sensor data, allowing tool SMEs to quickly investigate tool performance and misbehavior. By reducing the extra effort to merge, clean up, and analyze historically difficult log files, it has effectively reduced the time required to address these issues from days or weeks to a few moments.

Lavorro has worked closely with multiple customers to develop predictive failure models based on detailed tool data, resulting in reduced downtime, increased lifespan, and decreased operational costs. This has been a game-changer for many clients, providing them with an unprecedented level of insight into their tools' behavior and allowing them to take proactive measures to address potential issues.

Other notable benefits involving Lavorro's platform is the computation of measurements, particularly in the area of time-series analysis. This gives customers unique insights into variability they have not seen before, contributing significantly to process uniformity and allowing them to adjust their engineering solutions to correct any deviations.

Staying Ahead of the Game

At the helm of Lavorro stands Dr. Oberoi, an industry luminary renowned for his pioneering work in advanced technologies like Fab wide Predictive Yield Management, Cad Navigation and on-tool design based applications that revolutionized the semiconductor manufacturing landscape. Under his tutelage, the company has brought to bear a high level of yield improvement knowledge, now extending to the tool level while simultaneously providing cutting-edge framework for seamless tool-to-tool collaboration.

Out of all the ways in which Lavorro stands out from its competitors in the semiconductor industry, notable is its adoption of a collaborative engagement model. This approach entails working closely with semiconductor fabs and tool suppliers to identify complementary software solutions for tool performance, maximizing the benefits of its platform for all stakeholders.

Driven by its unwavering pledge to deliver tangible, measurable results and achieve operational excellence for its clients, Lavorro functions as an invaluable partner for any organization looking to optimize operations, streamline processes, and boost their bottom line. With its finger on the pulse of latest industry trends and developments, the firm is poised to continue blazing a trail toward a brighter, more efficient semiconductor manufacturing future.