What Are Diaphragm Pumps Used For?

Diaphragm pumps are versatile and widely used in various industries due to their unique design and ability to handle diverse substances. Their efficiency, durability, and adaptability can make them an essential component in many applications. These pumps are particularly favored for their ability to transfer liquids and gases without contamination, making them invaluable in specific industries where hygiene, precision, and safety are paramount.

But what are diaphragm pumps used for? Read on to learn more.

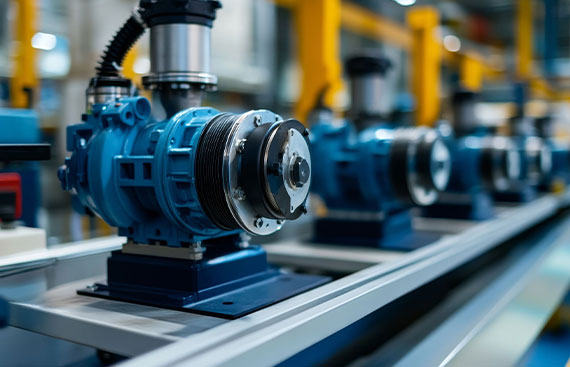

How Do Diaphragm Pumps Work?

Diaphragm pumps move a flexible diaphragm back and forth to create a pumping action. This movement changes the pressure within a chamber, allowing fluids or gases to be drawn in and expelled.

Some key components include:

- Diaphragm: This is the core part responsible for creating suction.

- Check Valves: This ensures a one-way flow of the substance.

- Pump Chamber: This houses the fluid or gas during operation.

Depending on the application, these pumps can be powered mechanically, pneumatically, or electrically.

Furthermore, as a trusted technology, diaphragm pumps have evolved to meet the demands of modern industries. For instance, seeking advanced solutions offered by companies such as knf.com/en/global can be an excellent decision as they can demonstrate their innovation and reliability in this domain.

Applications of Diaphragm Pumps Across Industries

Diaphragm pumps are versatile and reliable devices used across various industries for fluid transfer. Their ability to handle various viscosities, pressures, and chemical compositions makes them indispensable in manufacturing, pharmaceuticals, agriculture, and food processing.

Below are the applications of diaphragm pumps across industries:

-

Chemical Processing and Transfer

Diaphragm pumps are ideal for handling aggressive chemicals, including acids, solvents, and alkaline substances. Their corrosion-resistant materials ensure safe transfer without compromising performance.

Diaphragm pumps are used for dosing chemicals in industrial processes and are common in water treatment plants for adding chlorine or other substances.

-

Food and Beverage Industry

Hygiene is paramount in the food and beverage sector, and diaphragm pumps meet stringent standards for food safety. They’re used for transporting sauces, syrups, or other consumables and filling systems for beverages or liquid foods.

-

Pharmaceutical and Biotechnology Applications

Diaphragm pumps are vital in producing medicines and biotechnological products, where precision and contamination-free environments are critical. They’re used for transferring sensitive fluids like serums or vaccines and supporting laboratory systems in Research and Development.

-

Water and Wastewater Management

Diaphragm pumps play a crucial role in water treatment plants due to their reliability in handling viscous fluids efficiently. These centrifugal pumps are commonly employed to remove sludge, waste materials, and other contaminants, ensuring the smooth purification process.

Additionally, their durability and ability to operate in harsh conditions can make them ideal for delivering clean water supplies, especially in remote or underserved areas, where consistent performance is critical for maintaining access to safe drinking water.

Automotive and Manufacturing Sectors

In these industries, diaphragm pumps are essential for handling lubricants, adhesives, and coolants. They deliver precision in assembly lines and ensure consistent application of materials like sealants or oils.

Advantages of Diaphragm Pumps

Their adaptability makes diaphragm pumps a preferred choice across multiple sectors. Some of their standout benefits include:

- Chemical Compatibility: They can handle a variety of aggressive and sensitive substances.

- Self-Priming Capability: They operate efficiently without manual priming.

- Leak-Free Design: They reduce the risk of spills, ensuring safety and hygiene.

- Low Maintenance: Their durable construction minimizes repair needs.

- Energy Efficiency: They offer reliable performance with reduced power source consumption.

By understanding these benefits, industries can get the most out of diaphragm pumps for their operations.

Specialized Uses of Diaphragm Pumps

![]()

Diaphragm pumps are widely employed in specialized applications due to their precision and versatility. They are used in the following:

-

In Medical Equipment

Diaphragm pumps are integrated into medical devices such as ventilators and oxygen concentrators. Their ability to handle gases safely and efficiently can make them indispensable in healthcare.

-

In Laboratory Systems

In laboratories, diaphragm pumps are used for filtration, distillation, and vacuum applications. Their precision ensures accurate results in sensitive experiments.

-

In Oil and Gas Industry

The robustness of diaphragm pumps allows them to transport crude oil, drilling mud, and other challenging substances.

Selecting the Right Diaphragm Pump

Choosing the right diaphragm pump involves considering some essential factors. These include:

- Material Compatibility: Ensure the pump materials can handle the intended fluid or gas.

- Flow Rate Requirements: Match the pump capacity to the application.

- Environmental Conditions: Assess factors like temperature and low pressure.

With these factors in mind, industries can find the right electric diaphragm pump that ensures seamless business operations.

Conclusion

Diaphragm pumps are essential tools across a broad spectrum of industries. Their versatility, safety, and reliability make them indispensable in applications ranging from chemical transfer to medical equipment. Many companies continue to innovate in this field, ensuring that businesses have access to high-quality solutions for their operational needs. By understanding the specific uses and benefits of diaphragm pumps, industries can maximize their efficiency and achieve optimal results.

Read More News :

.jpg)